Table of Contents

The Process of custom polyester bandana Production

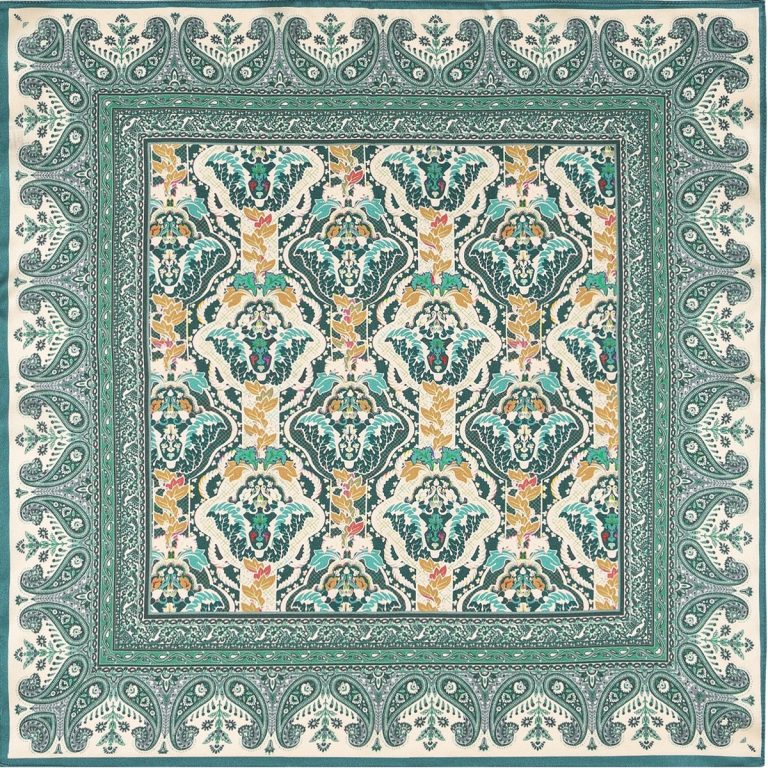

Custom polyester bandanas have become a popular accessory for individuals and businesses looking to add a personalized touch to their attire. These versatile pieces can be customized with logos, designs, or patterns to create a unique look that reflects the wearer’s style. In the USA, there are several manufacturers that specialize in producing custom polyester bandanas, custom made scarves printing, and scarves manufacturing.

The process of custom polyester bandana production begins with the selection of high-quality polyester fabric. This fabric is chosen for its durability, vibrant color retention, and ability to hold intricate designs. Once the fabric is selected, it is cut into the desired size and shape for the bandana. This step requires precision and attention to detail to ensure that each bandana is uniform in size and shape.

After the fabric is cut, it is time to print the custom design onto the bandana. This is where the expertise of custom made scarves printing comes into play. Using state-of-the-art printing technology, manufacturers are able to transfer intricate designs onto the polyester fabric with precision and accuracy. This process allows for vibrant colors and sharp details to be printed onto the bandanas, creating a high-quality finished product.

| custom design Silk bandana | printing |

| cap shawls | wool modal |

| for women | polyester diamond scarf exporter |

| custom ink Polyester scarf | 4c hair hijab |

Once the design is printed onto the fabric, the bandanas are then sewn together by skilled artisans. This step requires careful attention to detail to ensure that each seam is straight and secure. The edges of the bandanas are also finished to prevent fraying and ensure a clean, polished look.

After the bandanas are sewn together, they undergo a quality control inspection to ensure that they meet the manufacturer’s standards. This inspection includes checking for any defects in the fabric, printing, or stitching. Any bandanas that do not meet the quality control standards are discarded to ensure that only the highest quality products are shipped to customers.

Once the bandanas pass the quality control inspection, they are packaged and shipped to customers. Many manufacturers offer custom packaging options, such as individual poly bags or custom labels, to add a personalized touch to the finished product. This attention to detail ensures that customers receive a high-quality, custom polyester bandana that meets their specifications.

In conclusion, the process of custom polyester bandana production is a meticulous and detailed process that requires expertise and precision. From selecting high-quality fabric to printing intricate designs to sewing and finishing each bandana, manufacturers take great care to ensure that each product meets the highest standards of quality. By working with a reputable manufacturer that specializes in custom polyester bandanas, customers can create a unique and personalized accessory that reflects their individual style.

Exploring Scarf Manufacturing in the USA

Custom polyester bandanas, custom made scarves printing, and scarves manufacturers in the USA play a crucial role in the fashion industry. These products are not only stylish accessories but also serve practical purposes such as keeping warm in cold weather or protecting the skin from the sun. Behind the scenes of scarf manufacturing in the USA, there is a complex process that involves creativity, innovation, and attention to detail.

One of the key aspects of scarf manufacturing is the design process. Designers work tirelessly to create unique and eye-catching patterns that will appeal to consumers. They draw inspiration from various sources such as nature, art, and current fashion trends. Once a design is finalized, it is then transferred onto a digital file using specialized software. This digital file is then sent to the printing department where it is printed onto the fabric.

Custom made scarves printing is a crucial step in the manufacturing process. The printing department uses state-of-the-art digital printers to transfer the design onto the fabric. These printers are capable of producing high-quality prints with vibrant colors and intricate details. The type of fabric used for printing can vary depending on the desired look and feel of the scarf. Polyester is a popular choice for its durability and versatility.

After the fabric has been printed, it is then cut into the desired shape and size. Scarves can come in a variety of shapes such as square, rectangular, or even circular. The cutting process requires precision and accuracy to ensure that each scarf is uniform in size and shape. Once the scarves have been cut, they are then hemmed to prevent fraying and give them a polished finish.

Scarves manufacturers in the USA play a crucial role in overseeing the entire manufacturing process. They work closely with designers, printers, and cutters to ensure that each scarf meets the highest quality standards. Manufacturers also handle logistics such as sourcing materials, managing production schedules, and coordinating shipments to retailers.

In addition to custom polyester bandanas and custom made scarves printing, manufacturers also offer a range of customization options for their clients. This can include adding embellishments such as sequins, beads, or embroidery to the scarves. These customizations can add a unique touch to the scarves and make them stand out from the competition.

Overall, scarf manufacturing in the USA is a complex and intricate process that requires a high level of skill and expertise. From designing to printing to cutting, each step plays a crucial role in creating high-quality scarves that are both fashionable and functional. Custom polyester bandanas, custom made scarves printing, and scarves manufacturers in the USA are at the forefront of innovation in the fashion industry, constantly pushing boundaries and setting new trends.